0412-8229898

Product

Full oil-free high-pressure oxygen compressor

Product details

Full oil-free design, guide ring, piston ring, piston rod packing are all made of self-lubricating materials, 100% oil-free lubrication. Bearing parts are lubricated with high temperature resistant grease, not in contact with the compression medium, avoiding the pollution of the gas in the compression process and ensuring the purity of the gas. According to the actual gas situation, the compressor is divided into single-stage or multi-stage compression; structural form is divided into single-cylinder, double-cylinder, triple-cylinder, quadruple-cylinder and combined multi-cylinder structure; cooling mode is divided into air-cooled and water-cooled.

Microcomputer controller control, with high compressor discharge temperature, low inlet pressure, exhaust pressure, such as alarm stop function, high level of automation, stable and reliable operation of the compressor. According to the requirements of customers can be configured data remote display and remote control.

This series of compressors are mainly used for gas filling and bottle changing, and are also widely used in the oxygen industry, such as air separation plants, medical oxygen supply centers, and industrial fuel cutting.

Suction pressure: 0~ 1.0Mpa (G), exhaust pressure: ≤20 Mpa (G).

Oxygen is a kind of flammable gas, which will aggravate the combustion and explosion of burning substances. During manufacture and installation, the degreasing of parts and pipes in contact with oxygen should be strictly done.

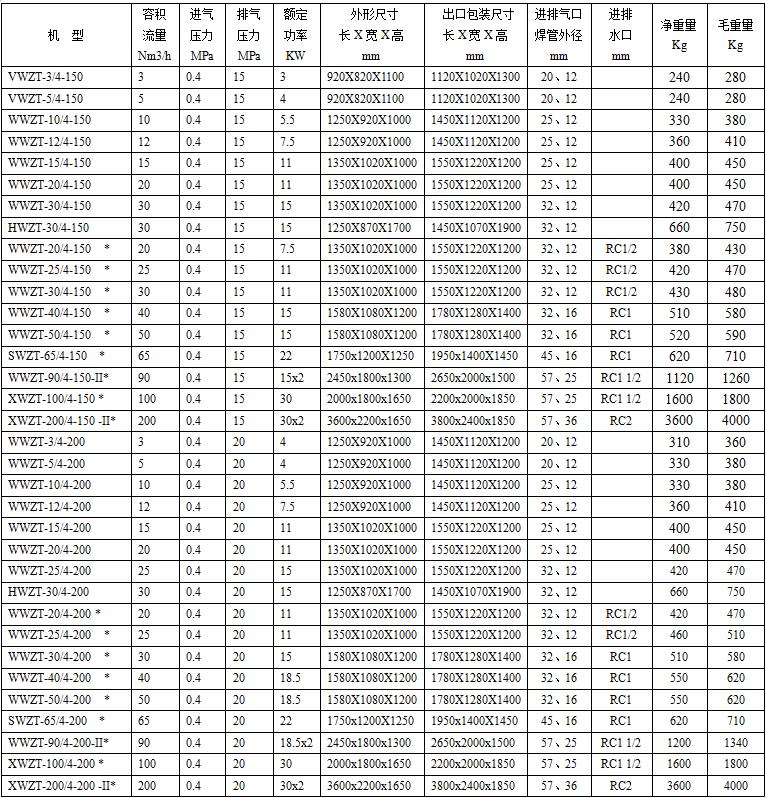

Oil-free High Pressure Oxygen Compressor Technical Specification Table Models marked with * are water-cooled.

The above parameters are for reference only, subject to the actual technical program. Models with larger flow rate and more inlet and exhaust pressures can be configured according to the specific requirements of users, please consult us further.